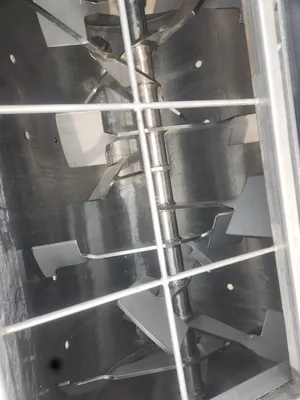

125 Cu.Ft. American Process Systems Jacketed Fluidized Paddle Blender with Choppers. Model FPB-125. 304 Stainless Steel construction. Jacket rated 125 PSI @ 350 degF / -20 degF. Main shaft driven by 50 HP, 1775 RPMi / 49 RPMo, 230/460 V. Has (8) choppers, (4) on each side, 15 HP, 3530 RPM, 208-230/460 V. Control Panel included. AMERICAN PROCESS SYSTEMS / EIRICH MACHINES, INC. Video of unit running available. Jacket passed hydrotest.

OEM:

Fluidizing Paddle Blender by American Process Systems was introduced to the market in 2003. It is the most innovative addition to our comprehensive line of APS blending equipment, offering a balance of mixing speed and efficiency with low equipment cost and consumed power.

Eliminates roll apart segregation caused by gravity when mixing ingredients of greatly varying density, shape, and size by mechanical fluidization. Fluidization is achieved by a combination of a defined geometry lifting action with a triple paddle, multi-zoned rotor turning about 80% faster than a traditional ribbon blender. Incredibly precise low Coefficient of Variation (CV) blends are achieved in less than two minutes for most powdered ingredients.

We use cookies to improve your experience. Privacy Policy.